Iringi ye-non-gear slawing enochungechunge lwe-010 enenani elincintisanayo

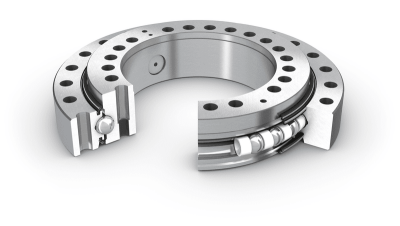

I-slewing bearing enamaphuzu amane yebhola inomthamo omkhulu wokulayisha omile futhi inganikeza ukuzungezisa okushelelayo.I-toothless ye-four point ball slewing bearing inezinzuzo zokusebenza kahle kokudlulisela phambili, umsebenzi onokwethenjelwa, kanye nesakhiwo esilula nesihlangene.Kukhona imigwaqo yomjaho emasongweni angaphakathi nangaphandle, futhi izindandatho zangaphakathi nangaphandle zixhunywe ngamabhola ensimbi.Amasongo angaphakathi nangaphandle anezimbobo ezifakwayo, ezingalungiswa kumathuluzi ahambisanayo namabhawudi, futhi iringi yangaphakathi ingaphendukiswa, noma iringi yangaphandle ingaphendukiswa njengoba kudingeka, noma izindandatho zangaphakathi nezingaphandle zingazungeziswa ku- ngesikhathi esifanayo.

Ama-slewing bearings ngokuvamile asebenzisa i-50Mn noma i-42CrMo njengezinto zokusetshenziswa.Imvelo kanye nekhwalithi yezinto zokusetshenziswa kunomthelela omkhulu ekusebenzeni kanye nempilo yesevisi ye-slewing bear.I-XZWD slewing bearings isebenzisa kuphela izinto ezivela kubahlinzeki abaqeqeshiwe.Sizokwenza ukuhlolwa okuqinile kuma-forgings, kufaka phakathi ukuhlolwa kwe-ultrasonic, ukuhlolwa kokuqina nokuhlolwa kwe-metallographic.

I-50Mn iyinsimbi yekhwalithi ephezulu ye-carbon structural.Inamandla aphezulu, ukunwebeka kanye nobulukhuni, futhi ivame ukusetshenziswa ngemva kokucisha kanye nokushisa.I-50Mn ayisebenzi kahle ngokushisela, futhi inomkhuba wokushisa ngokweqile nokuzwela nokucasuka.I-50Mn imvamisa isetshenziselwa ukwenza izingxenye ezinezidingo eziphakeme zokumelana nokugqoka kanye nomthamo wokulayisha, njengamagiya nama-giya shafts.

I-42CrMo impahla iyinsimbi ye-alloy, elungele kakhulu ukucutshungulwa kokusebenza.Inamandla aphezulu, ukuqina okuphezulu kanye nokuqina okuhle.Ukuguqulwa kwe-42CrMo ngesikhathi sokucisha kuncane kakhulu, futhi kunamandla aphezulu okukhasa kanye nokuqina ngaphansi kwezinga lokushisa eliphezulu.Uma kuqhathaniswa no-50Mn, i-42CrMo inamandla angcono okukhathala, kodwa izindleko ziphezulu.

Sicela uthole imininingwane engezansi yeringi engagezili igiya:

| No | Imodeli | Ubukhulu(mm) | Ukukhweza Ubukhulu | Ubukhulu Besakhiwo(mm) | Isisindo(kg) | |||||||||||

| D | d | H | D1 | D2 | n | Φ | dm | L | n1 | D3 | d1 | H1 | h | |||

| 1 | 010.20.200 | 280 | 120 | 60 | 248 | 152 | 12 | 16 | M14 | 28 | 2 | 201 | 199 | 50 | 10 | 20 |

| 2 | 010.20.224 | 304 | 144 | 60 | 272 | 176 | 12 | 16 | M14 | 28 | 2 | 225 | 223 | 50 | 10 | 22 |

| 3 | 010.20.250 | 330 | 170 | 60 | 298 | 202 | 18 | 16 | M14 | 28 | 2 | 251 | 249 | 50 | 10 | 25 |

| 4 | 010.20.280 | 360 | 200 | 60 | 328 | 232 | 18 | 16 | M14 | 28 | 2 | 281 | 279 | 50 | 10 | 28 |

| 5 | 010.25.315 | 408 | 222 | 70 | 372 | 258 | 20 | 18 | M16 | 32 | 2 | 316 | 314 | 60 | 10 | 44 |

| 6 | 010.25.355 | 448 | 262 | 70 | 412 | 298 | 20 | 18 | M16 | 32 | 2 | 356 | 354 | 60 | 10 | 49 |

| 7 | 010.25.400 | 493 | 307 | 70 | 457 | 343 | 20 | 18 | M16 | 32 | 2 | 401 | 399 | 60 | 10 | 56 |

| 8 | 010.25.450 | 543 | 357 | 70 | 507 | 393 | 20 | 18 | M16 | 32 | 2 | 451 | 449 | 60 | 10 | 62 |

| 9 | 010.30.500 | 602 | 398 | 80 | 566 | 434 | 20 | 18 | M16 | 32 | 4 | 501 | 498 | 70 | 10 | 85 |

| 10 | 010.30.560 | 662 | 458 | 80 | 626 | 494 | 20 | 18 | M16 | 32 | 4 | 561 | 558 | 70 | 10 | 95 |

| 11 | 010.30.630 | 732 | 528 | 80 | 696 | 564 | 24 | 18 | M16 | 32 | 4 | 631 | 628 | 70 | 10 | 110 |

| 12 | 010.30.710 | 812 | 608 | 80 | 776 | 644 | 24 | 18 | M16 | 32 | 4 | 711 | 708 | 70 | 10 | 120 |

| 13 | 010.40.800 | 922 | 678 | 100 | 878 | 722 | 30 | 22 | M20 | 40 | 6 | 801 | 798 | 90 | 10 | 220 |

| 14 | 010.40.900 | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | M20 | 40 | 6 | 901 | 898 | 90 | 10 | 240 |

| 15 | 010.40.1000 | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | M20 | 40 | 6 | 1001 | 998 | 90 | 10 | 270 |

| 16 | 010.40.1120 | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | M20 | 40 | 6 | 1121 | 1118 | 90 | 10 | 300 |

| 17 | 010.45.1250 | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | M24 | 48 | 5 | 1252 | 1248 | 100 | 10 | 420 |

| 18 | 010.45.1400 | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | M24 | 48 | 5 | 1402 | 1398 | 100 | 10 | 480 |

| 19 | 010.45.1600 | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | M24 | 48 | 5 | 1602 | 1598 | 100 | 10 | 550 |

| 20 | 010.45.1800 | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | M24 | 48 | 5 | 1802 | 1798 | 100 | 10 | 610 |

| 21 | 010.40/60.2000 | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | M30 | 60 | 8 | 2002 | 1998 | 132 | 12 | 1100 |

| 22 | 010.40/60.2240 | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | M30 | 60 | 8 | 2242 | 2238 | 132 | 12 | 1250 |

| 23 | 010.40/60.2500 | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | M30 | 60 | 8 | 2502 | 2498 | 132 | 12 | 1400 |

| 24 | 010.40/60.2800 | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | M30 | 60 | 8 | 2802 | 2798 | 132 | 12 | 1600 |

| 25 | 010.50/75.3150 | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | M42 | 84 | 8 | 3152 | 3147 | 162 | 12 | 2800 |

1. Izinga lethu lokukhiqiza lihambisana nemishini ejwayelekile ye-JB/T2300-2011, siphinde satholwa ama-Quality Management Systems(QMS) e-ISO 9001:2015 kanye ne-GB/T19001-2008 asebenzayo.

2. Sizinikela ku-R & D yokuthwala okwenziwe ngezifiso ngokunemba okuphezulu, inhloso ekhethekile nezimfuneko.

3. Ngobuningi bezinto ezingavuthiwe nokusebenza kahle kokukhiqiza okuphezulu, inkampani ingahlinzeka ngemikhiqizo kumakhasimende ngokushesha ngangokunokwenzeka futhi ifinyeze isikhathi sokuba amakhasimende alinde imikhiqizo.

4. Ukulawulwa kwethu kwekhwalithi kwangaphakathi kuhlanganisa ukuhlola kokuqala, ukuhlola ngokuhlanganyela, ukulawulwa kwekhwalithi okungaphakathi kwenqubo nokuhlolwa kwamasampula ukuze kuqinisekiswe ikhwalithi yomkhiqizo.Inkampani inemishini yokuhlola ephelele kanye nendlela yokuhlola ethuthukile.

5. Ithimba eliqinile lesevisi yangemuva kokuthengisa, ukuxazulula izinkinga zamakhasimende ngesikhathi, ukuhlinzeka amakhasimende ngezinsizakalo ezihlukahlukene.