Manje njengoba usukhethe okufaneleIndandatho yokubulalaNgemishini, sekuyisikhathi sokufaka isigaba sokufaka. Sicela ubheke lezi zinto ezine ezilandelayo ukuqinisekisa ukuthi uphumeleleukufaka.

1.Imininingwane yendawo ekhuphukayo

Kunezizathu eziningi zokuguqulwa kwendawo ekhuphukayo. Izibonelo ezejwayelekile zisukela kwinsimbi eyeqile phakathi kokuthwala kanye nendawo ekhuphukayo kuma-gaskets angafanele. Kodwa-ke, kungakhathalekile imbangela yokuguquguquka, umphumela awulungileukufakaokuthinta ubuqotho bomkhiqizo. Ukuguqulwa kwendawo ekhuphukayo kungadala izinkinga ezilandelayo: Ukugxilwa kokulayisha ekuvuneni; ukufundwa okungalungile ngesikhathi sokudla kwe-bolt; ukukhathala kwe-bolt; Inani lokuhluleka ukwehluleka.

Kunezizathu eziningi zokuguqulwa kwendawo ekhuphukayo. Izibonelo ezejwayelekile zisukela kwinsimbi eyeqile phakathi kokuthwala kanye nendawo ekhuphukayo kuma-gaskets angafanele. Kodwa-ke, kungakhathalekile imbangela yokuguquguquka, umphumela awulungileukufakaokuthinta ubuqotho bomkhiqizo. Ukuguqulwa kwendawo ekhuphukayo kungadala izinkinga ezilandelayo: Ukugxilwa kokulayisha ekuvuneni; ukufundwa okungalungile ngesikhathi sokudla kwe-bolt; ukukhathala kwe-bolt; Inani lokuhluleka ukwehluleka.

2. Lungisa ukubekwa uphawu kanye nokugcoba

Dlulisaukubheja okugoqiweKufanele ivalwe ukugwema noma yiziphi izici ezingathinta kabi ukusebenza, njengezinto ezingcolile nezinto ezilimazayo. Uhlobo lwe-seal olikhethayo luzohluka ngohlelo lokusebenza, ngakho-ke qiniseka ukuthi uthintana nochwepheshe othwala ngale nqubo. Lapho kucacisa indandatho ebunzi bokulala, ukuthambisa kanye nokuvumelanisa kufanele futhi kunikezwe okubaluleke kakhulu. Ngokuvamile, amabhethri azogcotshwa kwangaphambili. Lapho sebefakiwe kumkhiqizo wokugcina, kumele bavunyelwe ngesikhathi. Kweminye imikhiqizo, lokhu kuzoba ngumsebenzi wansuku zonke, kuyilapho kwabanye, kudingeka amafutha amaningi ngamahora ayi-100 okusebenza. Lezi zinqubo zokulungiswa kufanele zibhalwe ngokusobala kunoma yimiphi imanyumu ehlobene nomkhiqizo wokugcina.

3. Ukugcina Isitoreji

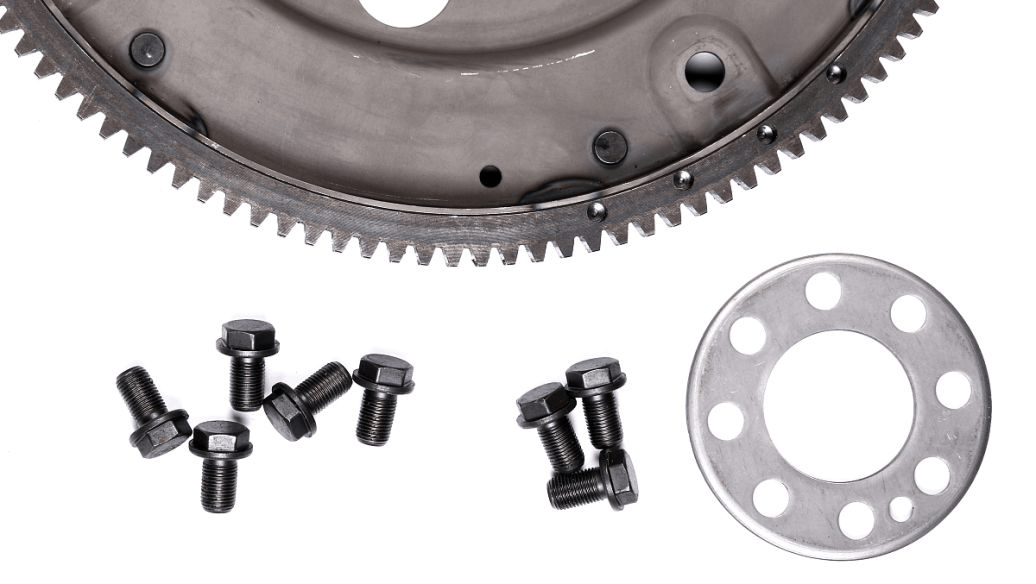

Ukulondolozwa kwesikhashana kwesikhashana kuvame ukubhekwa lapho ama-bearings ashiya ifektri. Uma uhlela ukuthola ama-bearings futhi ubashiye eshalofini isikhathi eside, qiniseka ukugcoba i amabombo ngaphambiliukufaka. Uma uletha kuwe nethimba lakho, kufanele futhi unake indlela amabhele aphathwa ngayo / agcinwe ngayo. Uma ingaphathwa kahle, ingaphezulu elikhulayo noma amazinyo egiya angalimala. Ukungcola kanye nezinye izinto ezingcolile kuzobuye kuqongelele kuIndandatho yokubulala, kubangeleukufakaubunzima.

4. Inqubo yokufaka efanele

Yize into yokugcina ibonakala isobala, kuvame ukunganakwa ukulandela okulungileukufakainqubo. Okokuqala, i-plug yokulayisha kanye negebe lokuqina lokuthwala kufanele litholakale endaweni ephansi yomkhiqizo. Uma lezi zici zibekwe endaweni esebenza kanzima, ukwehluleka ngaphambi kwesikhathi. Kufanele futhi uhlole izinhlanga ezithwala kulesi sinyathelo. Ngemuva kokuqinisa ama-bolts, umjaho othwala kufanele ube nxazonke. Okokugcina, okuncane, i-torque yokugcina ye-torque kanye ne-gear clearance kudinga ukubhekwa ngemuva kokufakwa. Uma ukuthwala kwakho kunezinkinga zokufaka, i-torque ebekile ngemuvaukufakakuzohluka kakhulu.

Inkampani yethu, i-Xuzhou Wanda Slewng Bearing Co, Ltd., ihlinzeka ngokusekelwa kwamahhala kwezobuchwepheshe kanye nensizakalo ephezulu yokuthengisa ngemuva kokuthengisa.

Isikhathi Seposi: Jan-29-2021