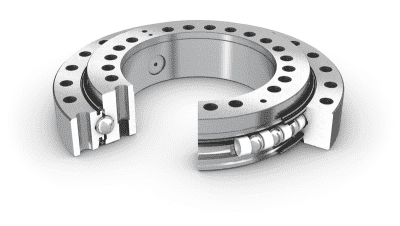

Emishini ye-CNC vertical Lathe, Theukuthwala okubuthayokungenye yezinto eziyinhloko ezibonisa umshini wonke ukusebenza futhi uqaphele ukunemba kwemishini ye-workpiepe. Sidinga ukuthi isebenze ngejubane eliphezulu futhi ibekezelela izisebenzi ezisindayo ngasikhathi sinye, ngokunemba okunembile ngokunemba kanye nokuqina okuphezulu kakhuluumthamo weTorque, no ukuthwala okubuthayo ukhiye wokuqedela ithebula lokusekelwa.Ukufakwa nokulungiswa kwamahhala kwe-guqukayoKuvinjelwe-buzileKunzima futhi, ukuqondaniswa kunzima ngokwengeziwe ukuqinisekisa, ukunemba okuphelele kwethebula kunzima ukuthuthuka.

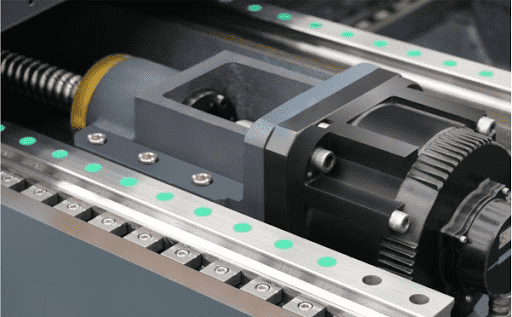

Ngenxa yalokho, iCompact ethe xaxaI-roller ewelekileKuvinjelweamabombozisetshenziselwa okunikeza izindleko zezindleko zokonga, izixazululo zokwakhiwa okwenziwe lula, isivinini esiphakeme sokukhawulelwa, ukunemba okuthuthukile nokuqina nokuqina, kanye nokuphakamaumthwalo wokuthwala umthamonobulukhuni. Lo mbhalo uchazaaukuhlaselaingomaneKuvinjelwe-buzileKu-CNC vertical Lathe ukufeza izakhiwo zabo zobunjiniyela obulungile.

Ukunemba kwe-1.Run

Ama-bulwing bukucija ukugijima-ngaphandleingahlukaniswa yaba runchronous run-out kanye nokuphelelwa yi-asynchronous, lapho ithonya lokuphelelwa okuvumelanayo ekuphelekeni okuphelele kwetafula lingancishiswa ngokugaya indawo yetafula.KaphaKuvinjelwe-buzile run asynchronous-ngaphandle, okuncane okugcinayoradial and axial run-ngaphandleye-Worthetable futhi ephakeme ukunemba okusebenzayo. EkukhetheniKuvinjelwe-buzile Ileveli yomkhiqizo nenembe, kunconywa ukuthi ungagxili kuphela Kuvinjelweukugijima umhlangano-ngaphandle, kepha kufanele kube nokuqonda okujulile komthelela weKuvinjelwe-buzileamazinga okunemba aphelelwe yi-asynchronous.

2.Shape nokubekezelela indawo

Le khasi ukuthwala okubuthayoumgodi izindawo ezikhuphukayona-indandatho yegiyadinga ukuthobeka, i-perpendicality, ukuzungeza kanye ne-cylindiricity ehambisana nayoukwenza kahleKuvinjelweamabombo. Ukulawula lezi zinhlobo nokubekezelela isikhundla akugcini ngokunikeza ukunemba komhlangano okungcono, kodwa futhi kugwema ukugxila kwengcindezi okubangelwa yi-eccentricity ngokweqile yele khasiIndandatho yokubulalaindandatho yangaphakathi nangaphandlefuthi i-relolongsImpilo yenkonzo yeKuvinjelwe-buzile. Maqondana namazinga wokucubungula efomu futhi Indandatho yokubulalaUkubekezelela isikhundla, Kunconywa ukubonisa thina ngqo ukufanisa KuvinjelweUkunemba.

3. I-Axial Axial Preload

Ukuhlolwa kokusika kwe-CNC mpo yelathe kubhekisisa kakhulu ubulukhuni bobuso bokuphela kwe-workpiece kanye nombuthano wangaphandle, futhi enye yezinkinobho zokunquma ukusebenza kwayo kubulukhuni bohlelo. Ubulukhuni bohlelo luhlanganisa ukuqina kwesakhiwo sohlaka, ukuqina kwe Kuvinjelwe-buzile, njll. Ubulukhuni be Kuvinjelwe-buzilekuvame ukuncikaukuthwala okubuthayoAma-Axial Preload.

Ngakho-ke, kubaluleke kakhulu ukubheka ithonya lokushisa nomthwalo, bese usethaI-axial preload yeKuvinjelwe-buzile.

Isikhathi sePosi: Aug-31-2020