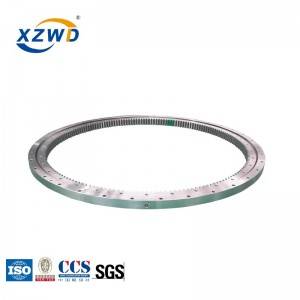

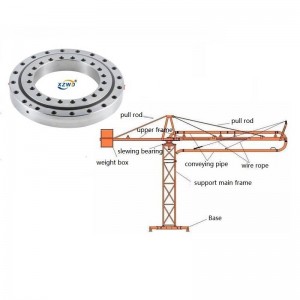

umsebenzi osindayo turntable amabhere nge Igiya yangaphandle slewing ring

Amandla okuxhumana nawokugoba wamagiya ngaphansi komthwalo wokugcina nokukhathala abalwe futhi aqinisekiswa ngokuya nge-ISO6336-1:2006, ISO6336-2:2006 kanye ne-ISO6336-3:2006 ngokulandelanayo.I-Sf ingu-1.48 futhi ukucaciswa kwe-gear mesh kulungiswa endaweni ephakeme kakhulu ye-radial ephumayoi-slewing beargear pitch indilinga.Ukususwa kwamazinyo okuncane kuvamise ukuba yi-0.03 kuya ku-0.04x modulus, futhi ukucaciswa kwe-gear mesh yamagiya aphina kuwo wonke umzuliswano kudinga ukuphinde kubhekwe ngemuva kokuqiniswa kokugcinai-slewing bear.

Ibhola lokuxhumana elinamaphuzu amane elinomugqa owodwa elijuba indandatho yangaphakathi yokunemba komshini webhola langaphakathi kanye nokunemba komshini wangaphakathi womjaho akukuphezulu, noma kukhona ukukhubazeka kwekhwalithi nokuntuleka kwamafutha okugcoba kurola womjaho womjaho kanye nokushayisana kwe-spacer, kuthinta ngokuqondile ukusebenza kahle kwendandatho yokugwaza. nomsindo, ngakho-ke lapho uhlola amaphutha endandatho yokubulala, ngezinye izikhathi ngokufaka ibhola esikhundleni sokunciphisa imvamisa yokwehluleka.

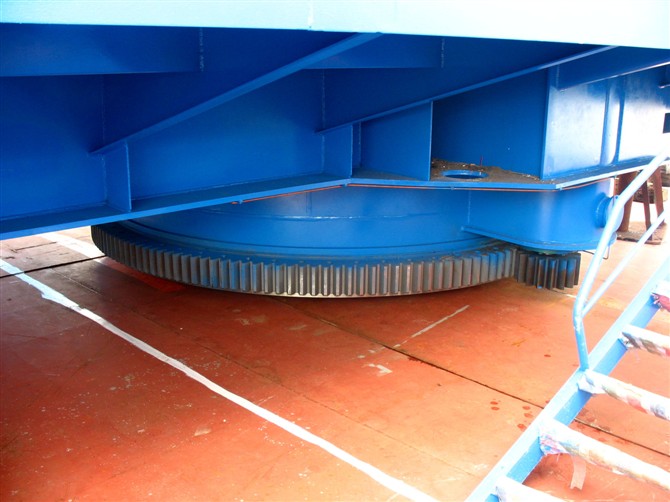

Ngenxa yegiya elingaphansi komthwalo ngemva kwesikhathi eside sokusebenza, kuzoba khona ucezu oluncane lwensimbi noma umucu wensimbi eduze komugqa wokumisa, ukugoba noma ukuququda ama-chips ensimbi, ukwakheka komgodi noma amazinyo.I-slewing bear bear tooth surface pitting kanye nokwanda kwesikhathi sokusebenza nokwanda ukuze umonakalo wezinyo le-slewing bear mesh, umsindo ojikelezayo we-tower crane nomthelela uyanda, umjikelezo womthelela phansi kwezinhlayiya zensimbi nokusheshisa ukuguga kwendawo yezinyo lendandatho yokubulala, ukwakha umjikelezo ononya.Ngaphezu kwalokho, ukukhiqizwa nokuhlanganiswa kwe-starter motor ku-slewing ring mechanism ineziphambeko zayo ukuze ikhiqize i-jitter yomthelela, futhi inqubo yokuzibandakanya yesondo lokushayela eline-slewing bear ayizinzile, okwandisa imvamisa ye-jitter nomsindo wokuphendula. ama-decibel.

Uma ikhwalithi yokushisela ingekho ezingeni, inkinga yokushisela idinga ukusetshenzwa kabusha futhi ifakwe kabusha.Ekulungiseni ukulungiswa kwe-welding ngeke nje kukhiqize ukucindezeleka okusha kwe-welding kanye nokuvuleka kwendawo yokufakwa ngomshini kuzoba nomthelela omkhulu, ngesikhathi esifanayo amandla okushisela akhiqizwa endaweni yokubhoboza ngokusebenzisa umzimba wangaphakathi wokugoqa kanye nomzila womjaho we-slewing ring nawo. dala umonakalo othile.Ukwengeza, amaphutha omhlangano ekuhlanganiseni kokukhiqiza, ukufakwa kwensimu kokucutshungulwa kwephinikhodi nokulayishwa kuqala kwebholithi nakho kungaveza umsindo ongajwayelekile noma ingxoxo uma izidingo zingahlangatshezwana nazo.

Iringi yokugenca amafomu ayinhloko awuhlobo lwangaphandle nolwangaphakathi, amagiya amakhulu namancane anezikhala kabi, kwesinye isikhathi aqinile, kwesinye isikhathi ayaxega, ezinyo leringithoni elihlabayo liphuma endaweni ephezulu ukuxhuma okuqinile kukhiphe umsindo.Ngakho inqubo yokukhiqiza ibalulekile.I-slewing bearing esanda kushiya ifekthri ingenzi lutho izokhipha umsindo we-steel rolling uniform, okuyinto evamile.Okufana nokukhala kweyunifomu evamile okuhambisana nokunye ukukhala okukhulu ngokungavamile akujwayelekile.Ziningi izizathu zokwehluleka.

1. Izinga lethu lokukhiqiza lihambisana nemishini ejwayelekile ye-JB/T2300-2011, siphinde satholwa ama-Quality Management Systems(QMS) e-ISO 9001:2015 kanye ne-GB/T19001-2008 asebenzayo.

2. Sizinikela ku-R & D yokuthwala okwenziwe ngezifiso ngokunemba okuphezulu, inhloso ekhethekile nezimfuneko.

3. Ngobuningi bezinto ezingavuthiwe nokusebenza kahle kokukhiqiza okuphezulu, inkampani ingahlinzeka ngemikhiqizo kumakhasimende ngokushesha ngangokunokwenzeka futhi ifinyeze isikhathi sokuba amakhasimende alinde imikhiqizo.

4. Ukulawulwa kwethu kwekhwalithi kwangaphakathi kuhlanganisa ukuhlola kokuqala, ukuhlola ngokuhlanganyela, ukulawulwa kwekhwalithi okungaphakathi kwenqubo nokuhlolwa kwamasampula ukuze kuqinisekiswe ikhwalithi yomkhiqizo.Inkampani inemishini yokuhlola ephelele kanye nendlela yokuhlola ethuthukile.

5. Ithimba eliqinile lesevisi yangemuva kokuthengisa, ukuxazulula izinkinga zamakhasimende ngesikhathi, ukuhlinzeka amakhasimende ngezinsizakalo ezihlukahlukene.