Amaphoyinti angu-4 webhola lokuxhumana le-angular turntable slewing ring

Iamabele okubulalaimboni iyimboni esebenzisa imali eningi futhi edinga ubuchwepheshe.Ngemva kweminyaka yentuthuko, the Xuzhouamabele okubulalaimboni iqale yasungula amazinga emboni aphelele uma kuqhathaniswa.Ucwaningo kanye

amakhono okuthuthukiswa kwezinkampani ezibulalayo athuthukisiwe kakhulu, kodwa uma kuqhathaniswa namazwe athuthukile, athuthukisa futhi akhiqiza ukuthuthukiswa kobuchwepheshe, imishini yokucubungula kanye nezinsimbi zokuhlola.Bangu

namanje amanye amagebe ezicini ezinjalo.

Ukuze kwandiswe isabelo sawo emakethe esezingeni eliphezulu, abakhiqizi be-Xuzhou abanamandla uma kuqhathaniswa abanamandla amakhulu obuchwepheshe baqhubeka bekhulisa utshalomali lwabo ku-R&D.Ngokwesibonelo, SlewingI-Ring ibilokhu ithuthukisa amazinga emboni kusukela ngo-2011. Izindinganiso zangaphakathi zebhizinisi eziqinile ukuze kuqinisekiswe ukuthi i-slewing bear geometry ithuthukiswa futhi;ukujula koqweqwe oluqinile kuyanda;impilo yesevisi yendandatho yokubulala iyanda;ucwaningo nokuthuthukiswa kwezinto ezivimbela ukubola kuyaqiniswa;futhi ukusetshenziswa kwendandatho yokuhlaba kuyakhuthazwa;Ukuthuthukiswa kwemishini, ukusetshenziswa kobuchwepheshe bokulingisa ikhompyutha ye

ukuqinisekiswa okusebenzayo komthamo wokuthwala indandatho, ukwakheka komkhiqizo kusayizi womklamo wokulungiselela.Ngaso leso sikhathi, amabhizinisi amaningi e-Xuzhou slewing bearing nawo aqala ukunaka ucwaningo nokusebenzisa indandatho yobuchwepheshe obuyisisekelo nobuchwepheshe obuhlobene.

Kufanele kushiwo ukuthi eminyakeni yamuva, i-xuzhou slewing bearings ithuthuke ngokushesha futhi ikhwalithi yama-slewing bearings iphezulu.Ngesikhathi esifanayo, kuhlanganiswe nokuthuthukiswa okuqhubekayo kwamandla okusebenza kwenkampani nokusebenza kahle kokukhiqiza, ama-slewing bearings e-Xuzhou ahlale egcina inzuzo yokuncintisana emakethe yasekhaya emakethe yasekhaya.

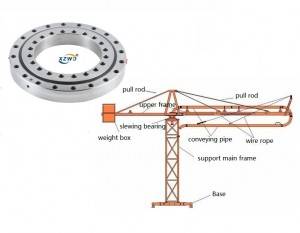

Abasebenzisi abaningi bebengazi okwanele mayelana nokufakwa kweringi yokushuba, ngokuvamile okuholela ekusebenzeni okungalungile kweringi ngenxa yamaphutha okufakwa noma amaphutha, njengokuzungezisa okuguquguqukayo, umsindo ongavamile, njll., namuhla okuholwa yi-Funda indlela yokufaka izindandatho ze-slewing. nokubulala ama-bearings ukuze wonke umuntu anciphise izinkinga namaphutha ekufakeni izindandatho zokubulala.

Okokuqala, ngaphambi kokufaka i-slewing ring, kuyadingeka ukuhlola indawo yokufaka yomshini omkhulu.Kudingeka ukuthi ilungu elisekelayo libe namandla anele, indawo yokuxhuma kufanele yenziwe ngomshini, futhi indawo engaphezulu kufanele ibe bushelelezi futhi ingabi nama-debris nama-burrs.Kulabo abangakwazi umshini ukuze kuzuzwe flatness edingekayo, amapulasitiki akhethekile anamandla omjovo aphezulu angasetshenziswa njengama-fillers ukuqinisekisa ukunemba kwendiza ekhuphukayo kanye nokunciphisa ukudlidliza.Iringi yokugwaza ye-slewing bear inendawo ethambile eqinile, ephawulwe ngo-S ekugcineni kobuso be-ferrule.Lapho ufaka, itheyiphu eguquguqukayo kufanele ibekwe endaweni engalayishiwe noma endaweni engeyona.

indawo ephindaphindiwe (imbobo yepulaki ihlezi isendaweni ethambile. ).

Okwesibili, lapho ufaka indandatho yokuhlinza, ukubeka i-radial kufanele kwenziwe kuqala, qinisa ama-bolts afakayo, futhi uhlole ukujikeleza kokuthwala.Ukuze kuqinisekiswe ukudluliswa okubushelelezi, amagiya kufanele ahlolwe ngaphambi kokuba amabhawodi afakayo aqiniswe.Lapho uqinisa ibhawudi, kufanele kube namandla okwanele okuqinisa ngaphambi kokuqina, futhi amandla okuqinisa ngaphambili kufanele abe ngu-70% womkhawulo wesivuno sempahla yebhawodi.Ama-bolts afakayo kufanele afakwe ama-washers ayisicaba.Akuvunyelwe ukusebenzisa ama-spring washers.Ngemuva kokuqedwa kokufakwa kwe-slewing bear, ifakwa ekusebenzeni.Ngemva kwamahora angu-100 okusebenza okuqhubekayo, kuyadingeka ukuhlola ngokugcwele ukuthi i-torque eqiniswa ngaphambili yebhawudi efakwayo iyahlangabezana yini nezidingo.Ukuhlola okungenhla kuphinda kanye njalo emahoreni angama-500 wokusebenza okuqhubekayo.

Okwesithathu, indandatho yokubulala kufanele igcwaliswe ngenani elifanele lamafutha ngemva kokufakwa, futhi kufanele igcwaliswe ngamabhorethi e-side slewing ukuze amafutha asakazwe ngokulinganayo.Ngemva kwesikhathi sokusebenza, indandatho yokubulalaukuzala kuzolahlekelwa nakanjani ingxenye yamafutha.Ngakho-ke, indandatho yokubulala kufanele igcwaliswe kanye njalo emahoreni angama-50 kuye kwayi-100 ekusebenzeni okujwayelekile.Okwama-slewing bearings asebenza ezindaweni ezishisa kakhulu noma ezinothuliizimo, isikhathi sokwengeza amafutha okugcoba kufanele sibe sifushane ngokufanelekile.Lapho umshini uzovalwa ukuze ugcinwe, kufanele futhi ugcwaliswe ngamafutha anele.

4. Ngesikhathi senqubo yokuthutha, ama-bearings kufanele abekwe ngokuvundlile ezimotweni.Kufanele kuthathwe izinyathelo zokuvimbela ukushelela nokuvimbela ukudlidliza.Uma kunesidingo, engeza izisekelo ezisizayo.

5. Ama-bearings kufanele abekwe avundlile endaweni eyomile, engenamoya, neyisicaba.Isitoreji kufanele sihlukaniswe namakhemikhali nezinye izinto ezigqwalile.Uma amasethi amaningi ama-bearings edinga ukupakishwa futhi apakishwe, amathathu noma ngaphezulu alinganayo-ukuphakama kwama-spacers okhuni kufanele kubekwe ngendlela efanayo endaweni ejikelezayo phakathi kwesethi ngayinye, futhi ama-spacers aphezulu naphansi kufanele abekwe endaweni efanayo.Ama-Bearings adinga ukuqhubeka agcinwe ngale kokugqwalaIsikhathi kufanele sihlanzwe futhi singagqwali futhi.

1. Izinga lethu lokukhiqiza lihambisana nemishini ejwayelekile ye-JB/T2300-2011, siphinde satholwa ama-Quality Management Systems(QMS) e-ISO 9001:2015 kanye ne-GB/T19001-2008 asebenzayo.

2. Sizinikela ku-R&D yokugwaza okwenziwe ngokwezifiso ngokunemba okuphezulu, inhloso ekhethekile nezimfuneko.

3. Ngobuningi bezinto zokusetshenziswa kanye nokusebenza kahle kokukhiqiza okuphezulu, inkampani ingahlinzeka ngemikhiqizo kumakhasimende ngokushesha ngangokunokwenzeka futhi ifinyeze isikhathi sokuba amakhasimende alinde imikhiqizo.

4. Ukulawulwa kwethu kwekhwalithi kwangaphakathi kuhlanganisa ukuhlola kokuqala, ukuhlola ngokuhlanganyela, ukulawulwa kwekhwalithi okungaphakathi kwenqubo nokuhlolwa kwamasampula ukuze kuqinisekiswe ikhwalithi yomkhiqizo.Inkampani inemishini yokuhlola ephelele kanye nendlela yokuhlola ethuthukile.

5. Ithimba eliqinile lesevisi yangemuva kokuthengisa, ukuxazulula izinkinga zamakhasimende ngesikhathi, ukuhlinzeka amakhasimende ngezinsizakalo ezihlukahlukene.